Vacuum Brazing Furnace Structure

The structure of the vacuum brazing furnace consists of furnace body, heating elements, vacuum system, etc, click for more information.

The structure of the vacuum brazing furnace consists of furnace body, heating elements, vacuum system, etc, click for more information.

This article explains the principles, process, influencing factors, and applications of M strip vacuum brazing for nickel-based alloys.

Titanium alloy vacuum brazing prevents oxidation, ensures high-strength bonds, is widely used in aerospace, medical, and electronics fields.

Vacuum brazing is a brazing process performed in a vacuum. It is commonly applied in industries with high welding quality requirements.

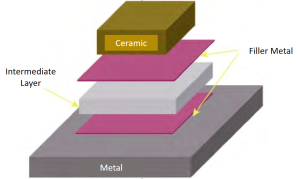

Brazing is a process that joins metal parts by melting a filler metal without melting the base material. What Brazing Processes Do You Know?

Copper, Stainless Steel, Aluminum, Titanium, Nickel, Precious Metals, Hard Alloys, etc. materials are Suitable for Brazing.

Brazing is a metal joining technique that uses molten filler at high temperatures to connect metals, offering high strength, etc.

In early May 2024, the vacuum brazing furnace produced by Fengpu Technology Co., Ltd. successfully passed the on-site acceptance of Ningbo customers.

On the morning of December 18, 2023, Li Xiaotong, the district party secretary and the first secretary of the Party Working Committee of Lukou Economic Development Zone, and his party visited Fengpu Technology company for research.

Hunan Fengpu Technology Co., Ltd. is a high-tech new enterprise that relies on semiconductor converter technology and integrates scientific research and development, production and operation.

If you need products or solutions for electric industrial furnaces, please feel free to contact us.

Looking forward to your contact.